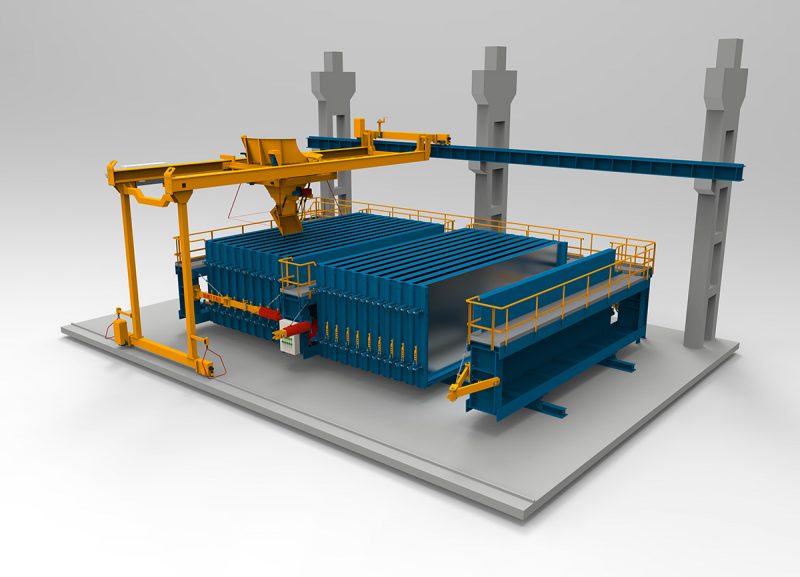

Vertical battery formwork

The vertical battery formworks are designed for the production of big flat elements as solid walls of variable thickness (from 80 mm. to 300 mm.) with passive reinforcement. The smooth finishing of both the wall sides are of high quality.

The system is very flexible: it allows manufacturing elements of various thicknesses, widths and lengths. These plants are designed and manufactured in accordance with each customer’s specific needs.

The battery consists of various moving casting sections, parallel to each other.

A formwork can manufacture elements up to a maximum length of 12.000 mm. and a maximum height of 4.000 mm., by 15 + 15 casting sections (cavities). The daily production output can reach up to max. 1.400 sq.mt.

The thickness of the wall to be manufactured is defined by the formwork profiles placed at the base and along the sides, in-between two shutters.

It is possible to equip these systems also with:

- hydraulic translation handling of the cavities;

- lower / upper rubber-steel chamfers;

- special design casting joint;

- radio controlled handling management system.

- automatic concrete distributor.

Moreover, it is possible to implement this system with:

- concrete compaction system by electric, high-frequency radio controlled vibrating installation;

- accelerated concrete curing system by using steam, water, oil or electricity. Electronic management of curing cycles;

- special casting mouldings with magnetic fixing system;

- access footbridges and ladders with safety parapets to work in the upper section.

OLMET ITALY equipment is made of high quality casting side plates of 10 mm. thickness, designed for lasting and guaranteed to manufacture elements having low tolerances on dimensional variations.

It is possible to use Self Compacting Concrete (CSS) thanks to rubber gaskets ensuring total sealing against leaking.

Precast elements

By these precasting technological solutions you can manufacture precast elements such as the following:

Strictly necessary cookies

Strictly necessary cookies

Functionality cookies

Functionality cookies

Tracking cookies

Tracking cookies Targeting and advertising cookies

Targeting and advertising cookies