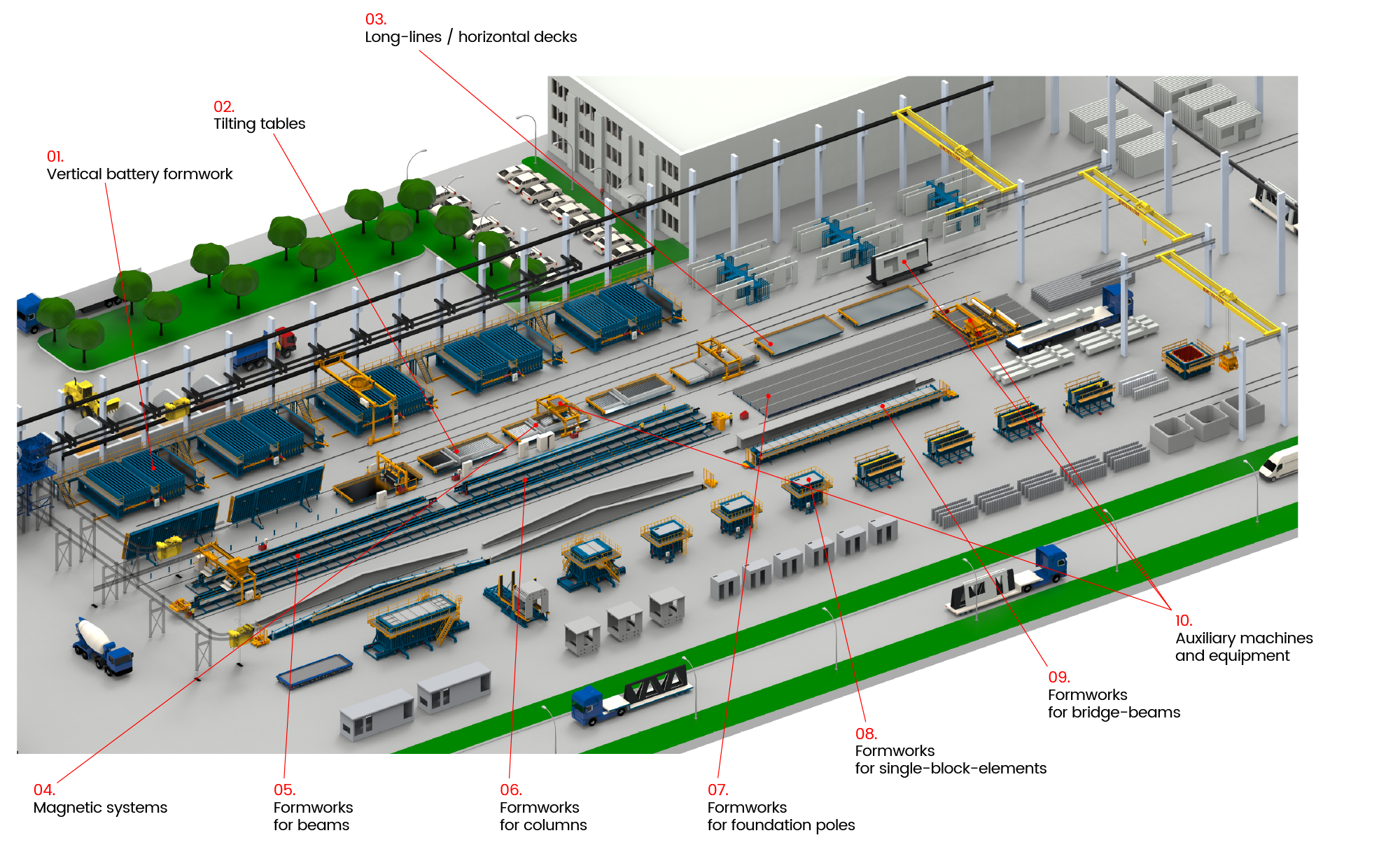

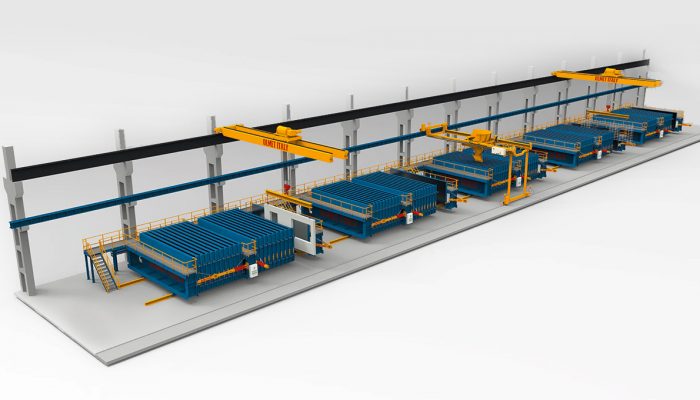

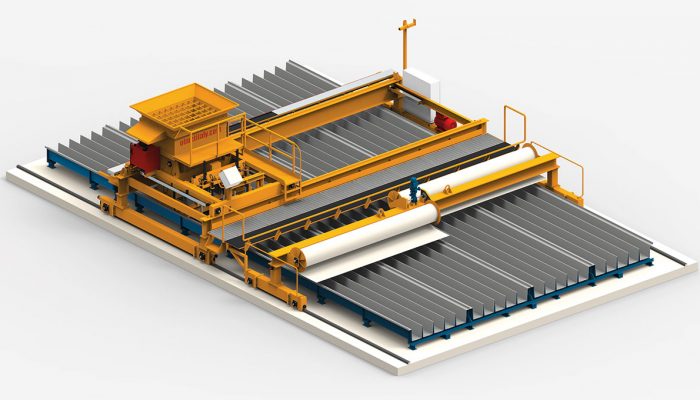

Complete installation

Olmet Italy can design and manufacture single machines and complete plants for industrial precasting, based on the specific requirements of each and every customer. They enable the user to carry out advanced production processes to manufacture high quality products in an efficient, cheaper and flexible way. . Each production line can be integrated with others and each plant can be further implemented in the course of time, as far as automation and efficiency are concerned.

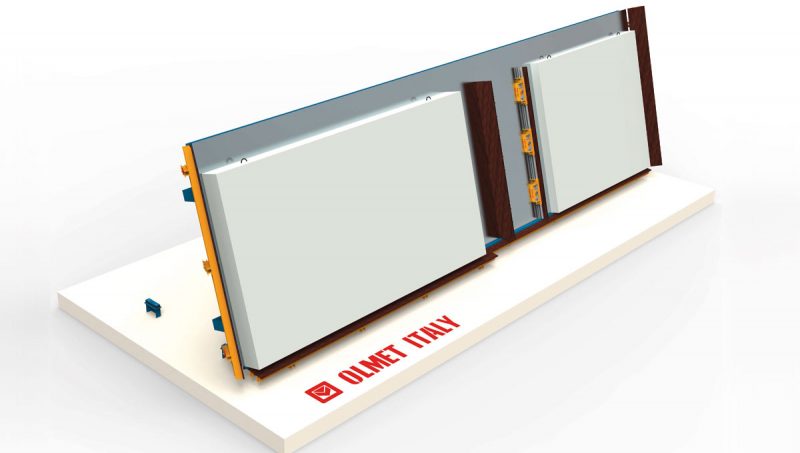

01.

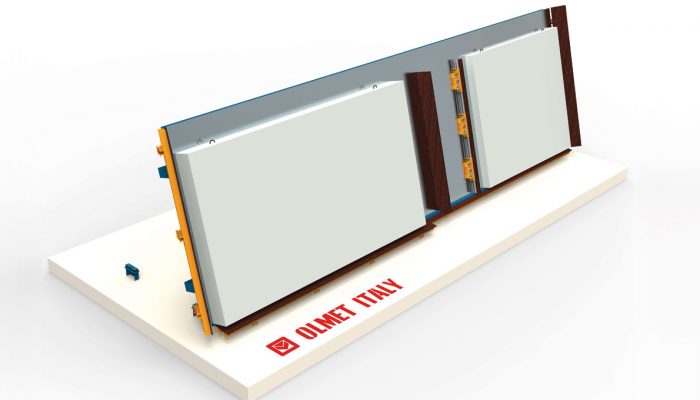

Vertical battery formwork

The vertical battery formworks are designed for the production of big flat elements as solid walls of variable thickness (from 80 mm. to 300 mm.) with passive reinforcement. The smooth finishing of both the wall sides are of high quality. The system is very flexible: it allows manufacturing elements of various thicknesses, widths and lengths. These plants are designed and manufactured in accordance with each customer's specific needs. The battery consists of various moving casting sections, parallel to each other. A formwork can manufacture elements up to a maximum length of 12.000 mm. and a maximum height of 4.000 mm., by 15 + 15 casting sections (cavities). The daily production output c...

Discover

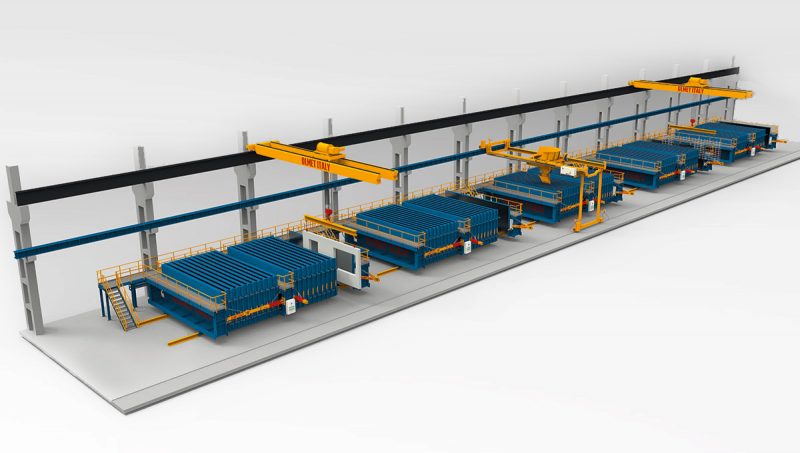

02.

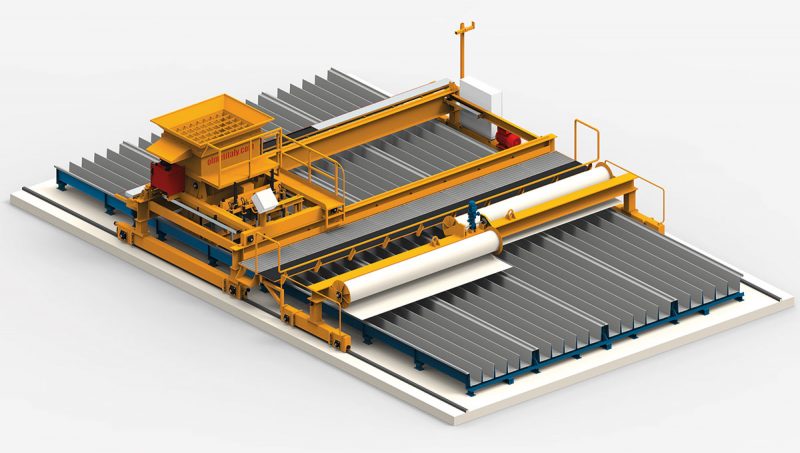

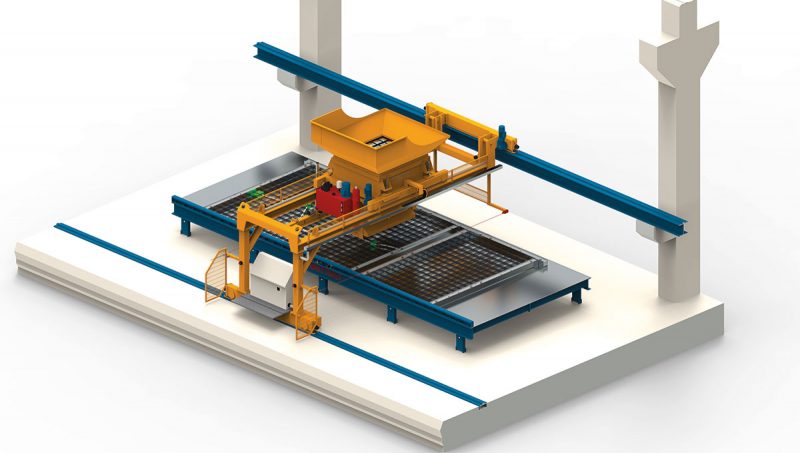

Tilting tables

Tilting tables are the ideal solution for manufacturing flat elements as slabs, solid walls and multi-layer panels with passive reinforcement and limited thickness. The system is very flexible, allowing to manufacture elements of various thicknesses, widths and lengths. These installations are manufactured according to each customer’s specific requirements. The tables can have up to 20 mt. length, max 5.000 mm. width and max 1.100 kg/sq.mt. load bearing capacity. It is possible to equip these side and longitudinal formwork systems with: hydraulic tilting system, variable in height; hydraulic handling system, movable in width; lower/upper rubber-steel gaskets; special des...

Discover

03.

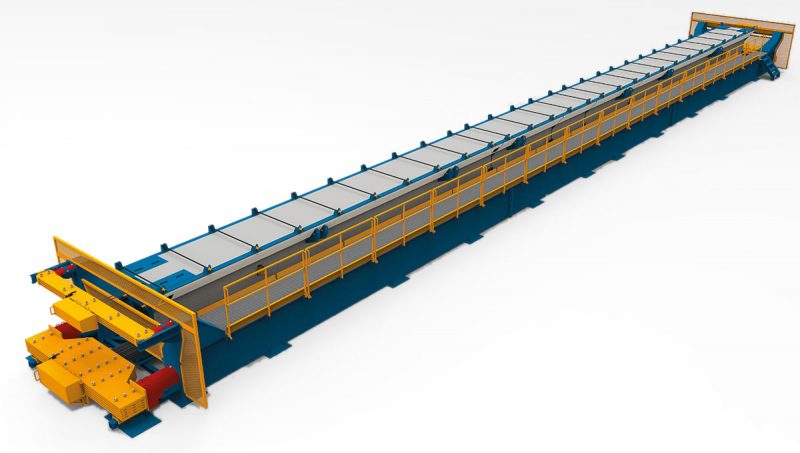

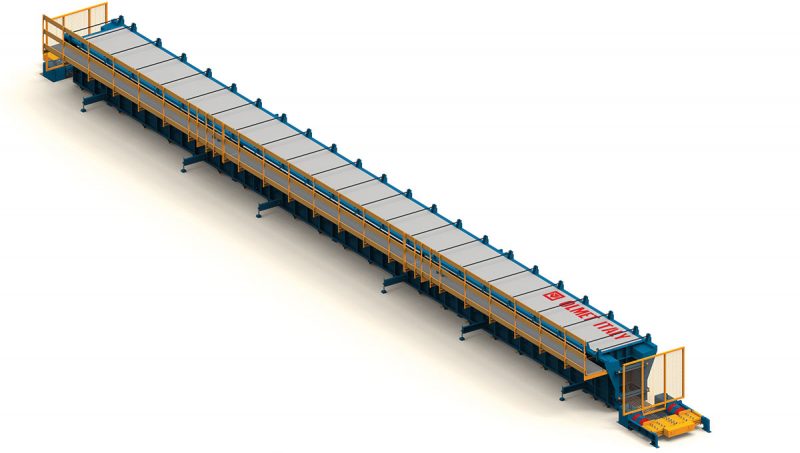

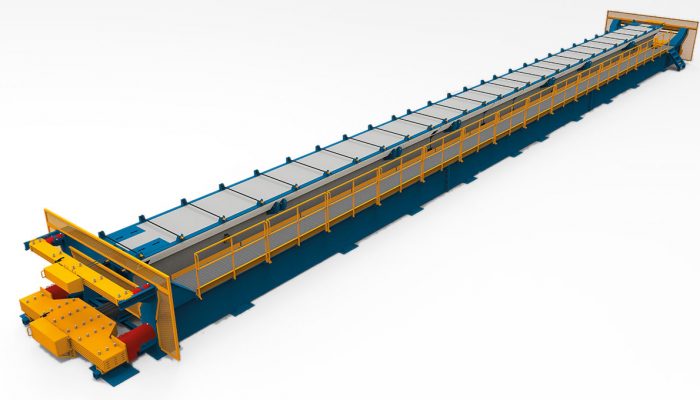

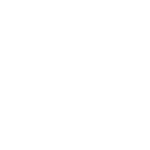

Long-lines / horizontal decks

Long-lines or horizontal decks are the ideal formworks for manufacturing flat elements as slabs, solid walls and multi-layer panels with passive or pre-stressed reinforcement. The system is very flexible, allowing to manufacture elements of various thicknesses, widths and lengths. These installations are manufactured according to each customer’s specific requirements. The maximum length of these systems is 150 mt, therefore enabling a daily production output of over 350 sq.mt. It is possible to equip these side and longitudinal formwork systems with: hydraulic tilting system, variable in height; hydraulic handling system, movable in width; lower/upper rubber-steel gaskets; s...

Discover

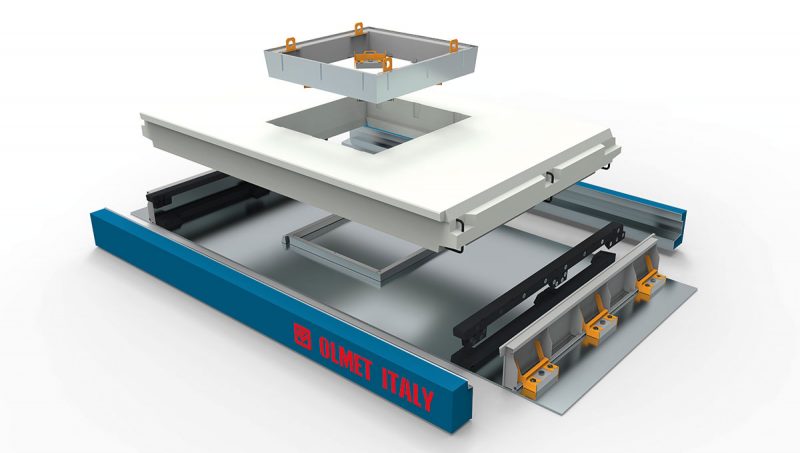

04.

Magnetic systems

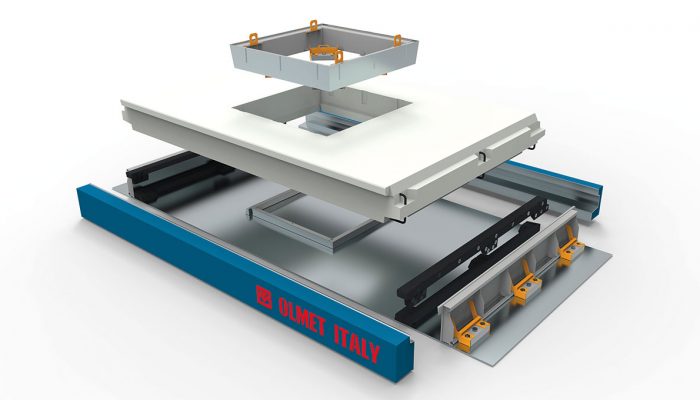

Various series of shutters and casting separators with integrated magnets. Besides a wide range of typical magnetic systems, Olmet Italy can design also custom-made accessories in accordance with each and every customer’s specific requirements.

Discover

05.

Formworks for beams

Formworks for beams are advanced systems to manufacture high quality concrete elements in an efficient and affordable way, with maximum flexibility in use. These machines have been developed year by year through the continuous research carried out by the OLMET ITALY designing team. They are completely automatic and designed as modules, so that one can use them to manufacture beams of so many different cross-sections by varying all their dimensions (x y z w). The automatic handling to change the dimensions is usually carried out by means of hydraulic cylinders or it is electronically operated by means of electro-mechanical devices. It can be remote-controlled as well. The safety of our ma...

Discover

06.

Formworks for columns

The formworks for columns or pillars are extremely versatile and easy-to-use machines. The fast assembling system for formwork components to manufacture the console or to change the pre-cast element section, allows to change even every day the type of element to be manufactured. The rubber-steel profile with triangle chamfer having section 10 x 10 , 15 x 15 or 20 x 20 mm. with 45° angle makes the corners perfectly sealed. It is possible to manufacture also columns with sharp edges by using rubber-steel gaskets. The unlocking/locking movements of the side elements or shutters and the bottom plate lifting to change the section are operated by means of advanced handling systems. T...

Discover

07.

Formworks for foundation poles

The formworks for manufacturing foundation poles (with passive reinforcement or pre-stressed) are battery-type systems offering noteworthy advantages in terms of production output quantities, speed and product quality. They do consist of: a base framework manufactured from longitudinal and transverse commercial profiles of huge thickness, suitable to bear the effects of vibration; the required number of cavities with a tray-shape (having a fixed dimension square section, with the minimum slope required for demoulding); the corresponding set of “double-face” casting separators (flat at one edge and tapered at the other one); vibrating installation and accelerated curing insta...

Discover

08.

Formworks for single-block-elements

The formworks, optimized to manufacture single-block multi-section concrete elements within short transformation times, enable the operator to manufacture a wide range of pre-cast concrete elements as they are manufactured as modules to be differently combined. Formworks belonging to this category are for example cabins for power sub-stations, garages, dwelling units, elevator shafts, bath cells (bathrooms and toilets), ventilation blocks, staircases, septic / sewage tanks, water reservoirs and many other concrete elements. The Construction System by “SINGLE-BLOCK” elements assures smooth inner walls without ribs and a constant inner surface along all the horizontal sections. It makes...

Discover

09.

Formworks for bridge-beams

The precasting lines for bridge beams are huge plants which are built using steel profiles of increased section. Casting-side plates thickness usually ranges from 10 to 12 mm. The combination of steel profiles of increased section and large thickness casting-side plates ensures products complying with very low dimensional tolerances. Formworks are designed to manufacture different concrete product cross-sections, by modifying the formwork shape itself. This is made possible by semi-automatically controlled electro-hydraulic handling devices, which enable the operator to change the pre-cast element cross-sections within a few minutes. All the opening/closing movements of side elements and...

Discover

10.

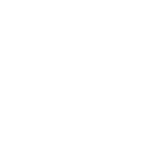

Auxiliary machines and equipment

It is possible to implement each formwork by adopting also auxiliary equipment that make it possible to automate some functions. In this way, the whole plant is implemented and the production output is increased, whereas the labour costs are reduced.

Discover

Components of the plant

Vertical battery formwork

The vertical battery formworks are designed for the production of big flat elements as solid walls of variable thickness (from 80 ...

Discover

Tilting tables

Tilting tables are the ideal solution for manufacturing flat elements as slabs, solid walls and multi-layer panels with passive re...

Discover

Long-lines / horizontal decks

Long-lines or horizontal decks are the ideal formworks for manufacturing flat elements as slabs, solid walls and multi-layer panel...

Discover

Magnetic systems

Various series of shutters and casting separators with integrated magnets. Besides a wide range of typical magnetic systems, Ol...

Discover

Formworks for beams

Formworks for beams are advanced systems to manufacture high quality concrete elements in an efficient and affordable way, with ma...

Discover

Formworks for columns

The formworks for columns or pillars are extremely versatile and easy-to-use machines. The fast assembling system for formwor...

Discover

Formworks for foundation poles

The formworks for manufacturing foundation poles (with passive reinforcement or pre-stressed) are battery-type systems offering no...

Discover

Formworks for single-block-elements

The formworks, optimized to manufacture single-block multi-section concrete elements within short transformation times, enable the...

Discover

Formworks for bridge-beams

The precasting lines for bridge beams are huge plants which are built using steel profiles of increased section. Casting-side pla...

Discover

Auxiliary machines and equipment

It is possible to implement each formwork by adopting also auxiliary equipment that make it possible to automate some functions. I...

Discover

Necessari

Necessari

Funzionali

Funzionali

Statistiche

Statistiche Marketing

Marketing